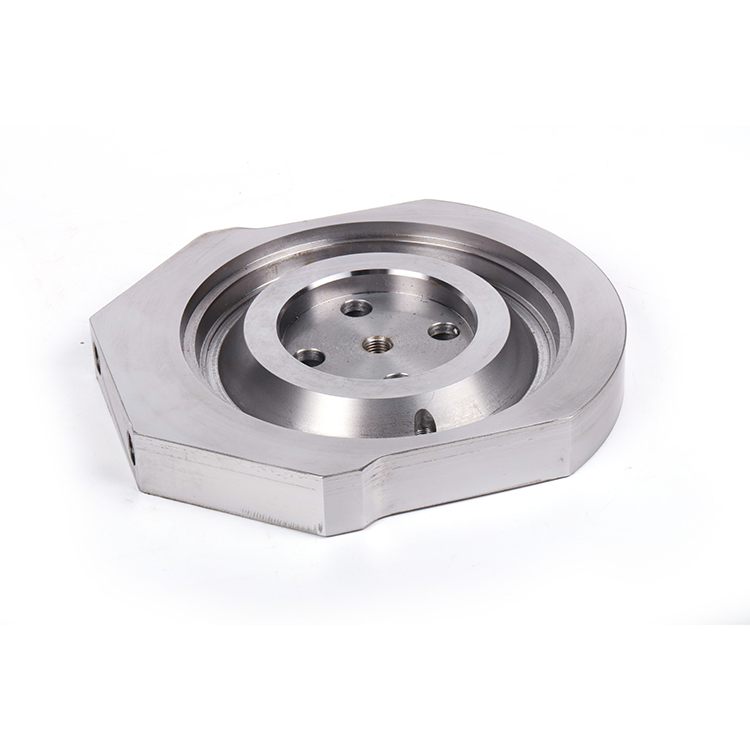

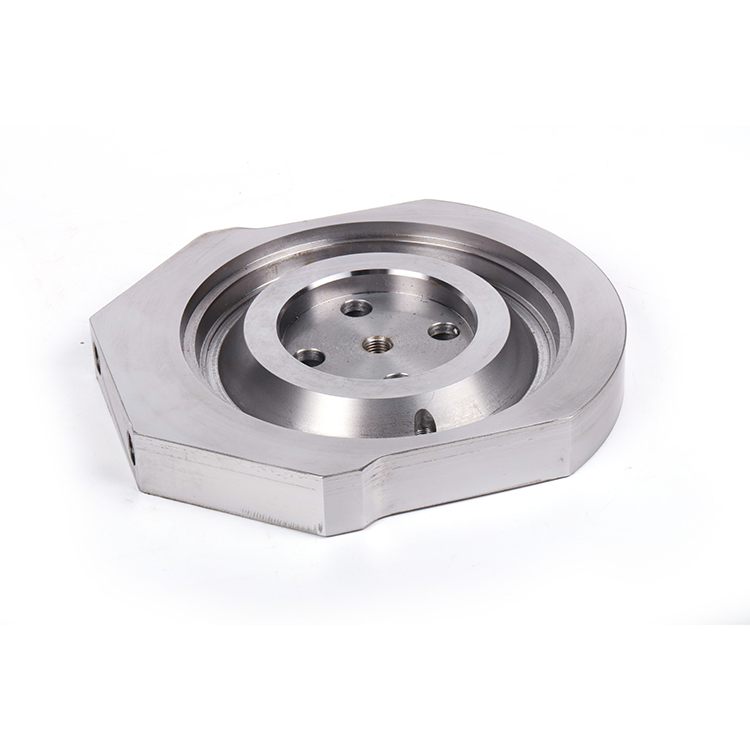

As placas de mecanizado de pezas de mecanizado de aceiro inoxidable CNC

As pezas producidas inclúen pezas de automóbiles , pezas de maquinaria agrícola , pezas de andamios de construción Válvula mariña e compoñentes de bomba e pezas hidráulicas, etc. arquitectónico, maquinaria, médica; Maquinaria de alimentos, válvulas e así por diante. O material que usamos aluminio; Bronce; Latón; Cobre; aceiro carbono; aceiro inoxidable e así por diante. Ao mesmo tempo, podemos ofrecer o mecanizado CNC; Fosfando; Procesamento de ennegrecemento; Galvanización de mergullo en quente: revestimento en po: pintura: chapa, montaxe para clientes.

Os produtos do 85% véndense ao exterior, os clientes son de América, Canadá, unión de Europa , etc.

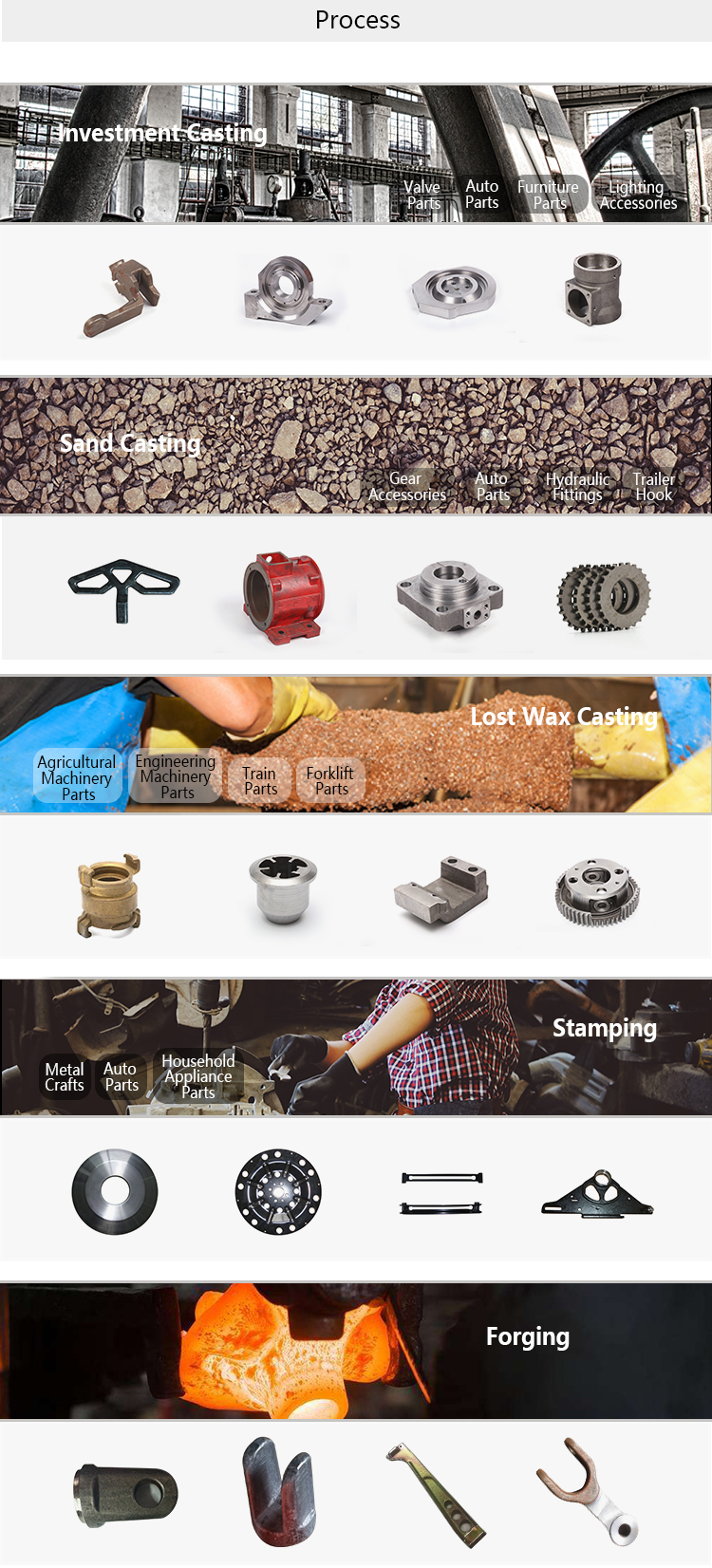

Estamos especializados en:

1. Casto de area (ferro gris, ferro dúctil, aluminio, etc.)

2. Casto de investimento (aceiro de carbono, aceiro inoxidable, aceiro de aliaxe, etc.)

3. Casting (aluminio, cinc, etc.)

3. mecanizado CNC (CNC Center, CNC Torno, Torno, Máquina de perforación, Máquina, Máquina de prensado, etc.)

Certificado: ISO9001: 2015, TS16949

|

Products

|

According to the customers'technical drawings or s amples

|

|

Casting Material

|

Cast Iron, ductile iron, Grey iron, GG25, GG20, GGG40, GGG50, GGG60 GGG70:

|

|

QT400-18,QT450-10,QT600-3QT700-2,FCD400,FCD450,60-40-18,65-45-12,ect.

|

|

Casting Product Weight

|

available from 0.02kg to 3000kg

|

|

Surface Treatment

|

Oxidation

|

|

Plating zinc

|

|

Painting

|

|

Hot galvanized

|

|

Powder coating

|

|

Electroplating

|

|

Sand blasting

|

|

Electrophoresis

|

|

Vbration Grinding

|

|

Inspection

|

*100% ins pection before shipping, offer the material reports and

mechanical property reports

|

|

*Control Plan and PPAP documents according to the clients'requirements

|

|

*ISO9001: 2015 quality control system

|

|

Extra Service

|

CNC machining servce in our machining workshop

|

|

Advantages

|

* The dimensions and outs ide shape are similar with investment casting

|

|

*The surface roughness is good from 2.5 to 25um(100 to 1000um

|

|

*The min thickness can meet 3 mm(0. 120inch)

|

|

*decrease the internal crack and keep close structure

|

|

*As no joint and defect the cleaning and machining work can be less

|

|

*it's cheaper because its a simpler process and the foam is cheaper than the wax

|