anel enrolado casting die titanium for forxing parte

Get Latest Price| Tipo de pagamento: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transporte: | Ocean,Land,Air |

| Porto: | NINGBO |

| Tipo de pagamento: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transporte: | Ocean,Land,Air |

| Porto: | NINGBO |

Marca: KST

| Tipo de paquete | : | bolsas de burbullas, cartón, caixas de madeira |

The file is encrypted. Please fill in the following information to continue accessing it

Forxa fría

Estamos especializados en:

1. Fundición de area (ferro gris, ferro dúctil, aluminio, etc.)

2. Casting de investimento (aceiro de carbono, aceiro inoxidable, aceiro de aliaxe, etc.)

3. Casting (aluminio, cinc, etc.)

4. Mecanizado (centro CNC, torno CNC, torno, máquina de perforación, fresadora, máquina de prensar, etc.)

Certificado: ISO9001: 2015, TS16949

|

Item Name

|

OEM customized rolled ring strainless steel casting die titanium forging part with investment casting

|

||

|

General Products

|

Metal Parts Solution for Vehicle, Agriculturemachine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

||

|

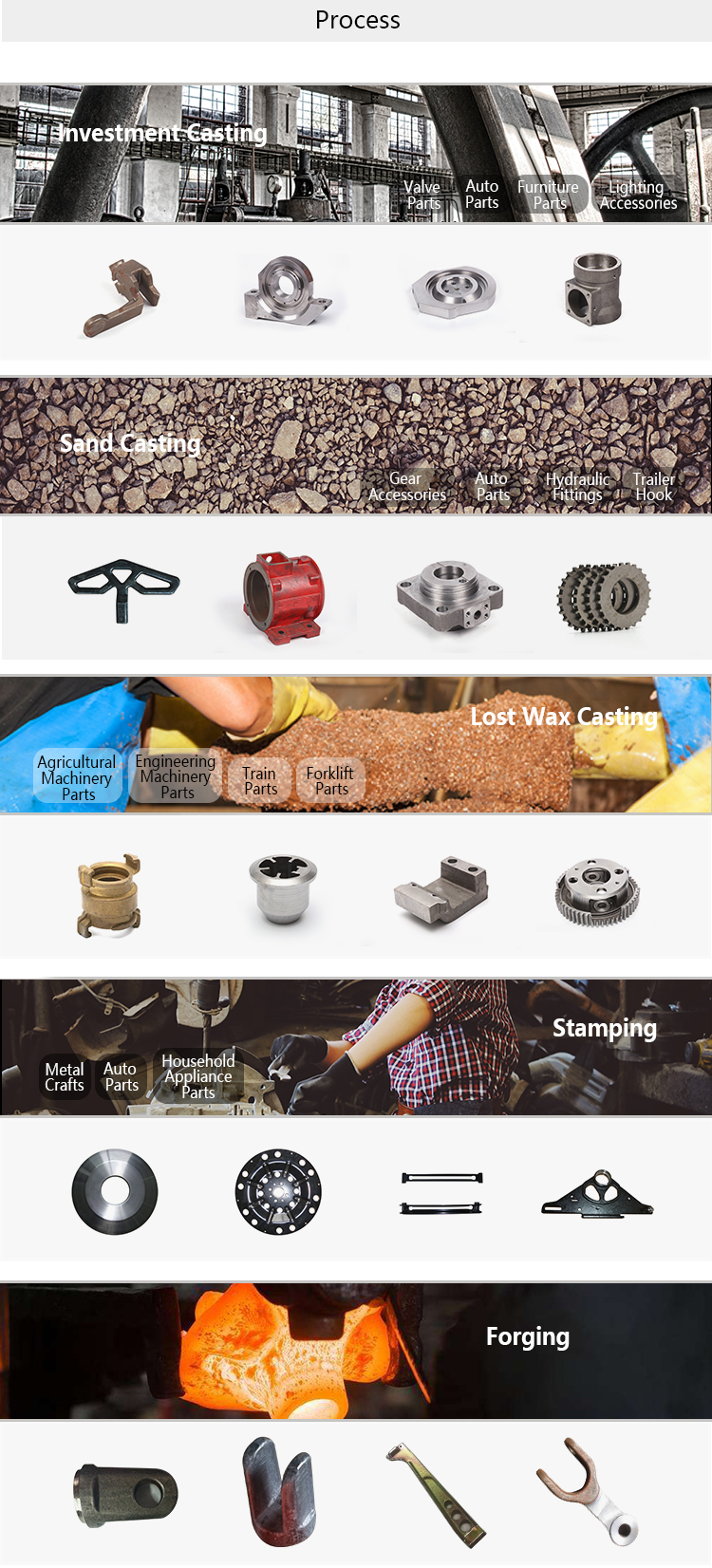

Process

|

Forging , Press

|

||

|

Blanks Tolerance

|

+/-0.3~+/-2 mm

|

||

|

Applicable Material

|

Carbon steel, Low Carbon steel, middle carbon steel, 40Cr, 20CrMnTi, 20CrNiMo etc.

|

||

|

Forging Blank Size

|

142 mm- 300mm or according to customer requirement

|

||

|

Blanks Weight

|

Range from 0.1kg-1000kg

|

||

|

Applicable Machining Process

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc.

|

||

|

Machining Tolerance

|

From 0.005mm-0.01mm-0.1mm

|

||

|

Machined Surface Quality

|

Ra 0.8-Ra3.2 according to customer requirement

|

||

|

Applicable Heat Treatment

|

Normalization , quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

|

||

|

Applicable Finish Surface Treatment

|

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting,

|

||

|

MOQ of mass production

|

100 pcs

|

||

|

Lead Time

|

25~45 days for steel forging metal parts

|

||

Declaración de privacidade: a súa privacidade é moi importante para nós. A nosa empresa promete non divulgar a súa información persoal a ningunha expansión con os seus permisos explícitos.

Encha máis información para que poida poñerse en contacto contigo máis rápido

Declaración de privacidade: a súa privacidade é moi importante para nós. A nosa empresa promete non divulgar a súa información persoal a ningunha expansión con os seus permisos explícitos.